Generally speaking,the chipload and cutting speed are the most concerned two cutting paramaters under which a tool works,Each is defined as below:

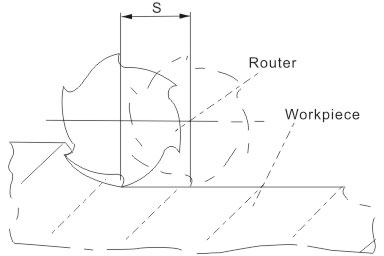

Cutting speed(VC):path cover by one cutting edge at the corresponding rotation within a given time unit.

usually stated in m/min

VC=d·π·n/1000 m/min

VC-Cutting speed in m/min

d-router diameter in mm

n-spindle rotaing speed in RPM

Chipload(S):work spindle feed in mm per revolution,mm/rev

Feed Rate(Fd):table feed rate in m per minute

Fd=S·n/1000 m/min

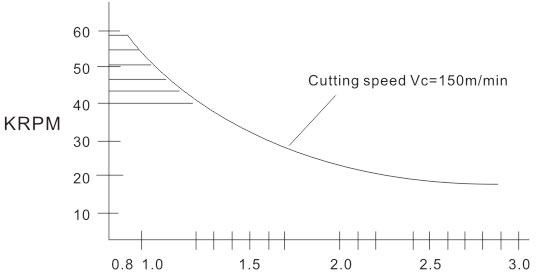

For most applications,the best suitable cutting speed Vc is150mm/min.

However,from the above chart,you can see that, for router dia.smaller than 1.2mm ,the practically used spindle rotations are much low than the theoretical ones ,which is limited by the maximum spindle power of the current routing machines.

Skype:richvertex@outlook.com

endmill@richvertex.com